A 15-minute intro to hobby CNC

In which the author tilts at windmills for a brief while.

If you want to sell your product to nerds, I think the safest bet is to just make them feel loved. The success of Arduino and Raspberry Pi had little to do with technological feats; it boiled down to writing hobbyist-friendly docs and then bootstrapping a DIY community that wouldn’t judge you for just wanting to blink some LEDs.

The same is probably true for 3D printing. All the hobbyist-accessible tech is finicky, constrained, and slow, but it’s carried by the vibrant community and the vendors that speak our language. In contrast, CNC milling — the industrial technology behind the bulk of household goods — continues to be gatekeeped by pros who sneer at any setup that runs on single-phase power and can fit in a suburban a garage.

About a decade ago, I tried to change this by publishing a 110-page treatise on hobby CNC. In retrospect, the attempt was pure lunacy: a leather-bound tome doesn’t scream “it’s easy”. So, let’s try something more suited for the TikTok age.

First, here’s my desktop CNC cutting a simple pattern in some scrap plastic. The two-minute video shows the process start to finish and in real time:

The machine uses computer-controlled movements to remove material with a spinning drill-like tool. The process is fast, predictable, and supremely accurate. It’s also capable of working in a variety of materials — rubber, plastic, wood, aluminum, and so forth.

CNC has a reputation for being noisy and messy, but this is not quite right. The mess is minor and manageable; we also own a resin printer, and the cleanup of that is far more of a pain. As for noise, it’s pronounced in metals. In softer materials, my vacuum cleaner is usually drowning out the mill.

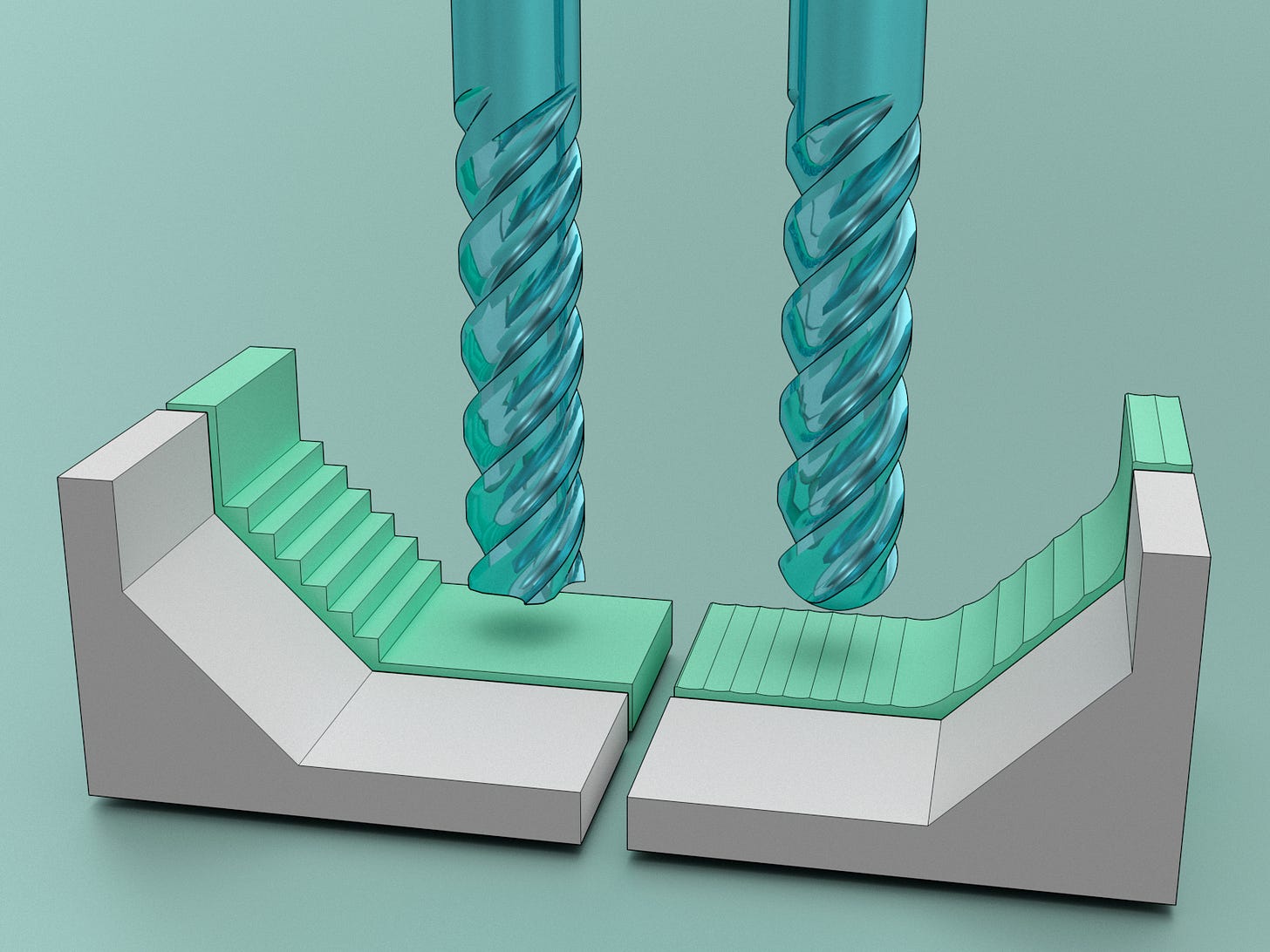

CNC cutting tools come in a variety of shapes. The two most common variants are shown below:

Common tool diameters range from 0.25 mm to 6 mm, but cutters as small as 0.1 mm — or as large as 25 mm — are available for specialized tasks.

Square endmills excel at machining flat surfaces, but can leave staircase patterns when parallel toolpaths are generated along a sloped geometry. Ball-nose tools produce gentler “scallops”, but leave more material in sharp corners. Some planning is necessary to design parts that can be easily made with your tools. That said, almost all household and industrial goods deal with this reality — and geometry constraints also exist for 3D-printed parts.

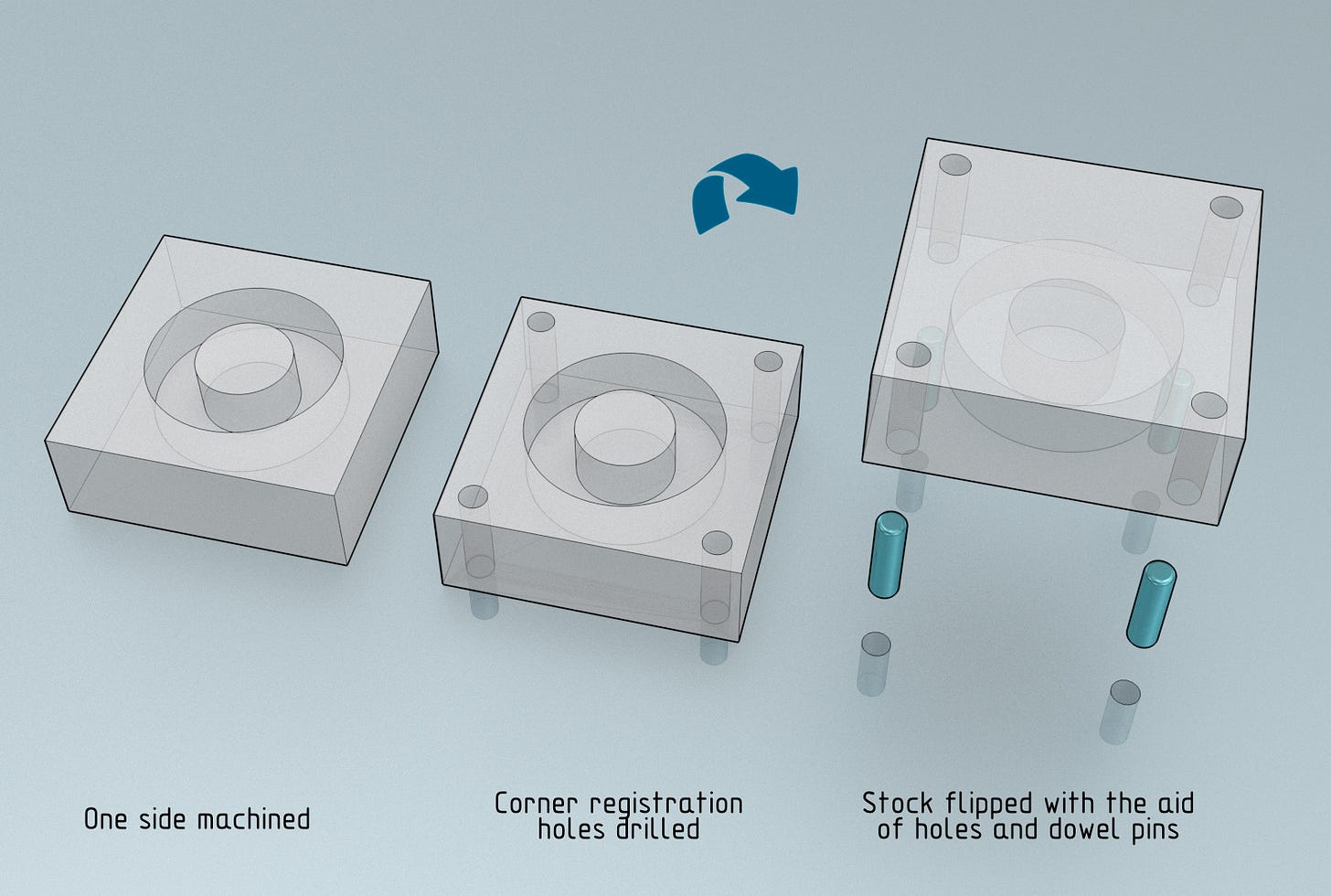

In the simplest variant of the process, the mill moves in three axes (XYZ), but the tool is always approaching the workpiece from the top; it would seem that you can only make parts with no undercuts and no features on the back. Not so: the most rudimentary solution is to manually flip over the workpiece with the aid of CNC-machined holes and steel dowel pins, then cut the other side:

On larger machining centers, it’s common to have a system that automatically rotates the workpiece around one or two axes, permitting unattended cuts from different angles — as well as continuous lathe-style operations. That said, when you’re not trying to run a big production line, operator-assisted flips (and tool changes) work just fine.

Competent desktop CNC systems cost more than entry-level 3D printers, but the difference isn’t huge. Neither tech is plug-and-play: there is a fairly steep learning curve to computer-aided design (CAD) and to materials science. And neither of these technologies should be the only trick up your sleeve: for basic tasks, such as making a couple of straight cuts, simpler tools produce results faster and with fewer opportunities for mistakes.

Still: if you’re a serious tinkerer, there’s no reason to fear the CNC mill.

I write well-researched, original articles about geek culture, electronic circuit design, algorithms, and more. This day and age, it’s increasingly difficult to reach willing readers via social media and search. If you like the content, please subscribe!

Thanks for the 110-page tome. I really got a lot out of it and eventually decided to give it a try. After waiting for ages, a really cheap MDX-15 came up on eBay and it worked well enough. So I learnt some FreeCad and knocked out this for a friend's birthday: http://www.ashurst.eu.org/download/tmp/gal-charlie-chocs/index.html

Other than cutting one side of a chess piece STL I downloaded from somewhere to test the machine, that's the first thing I ever did with CAD/CAM and your guide was instrumental in making it accessible.

Thanks!

Watched servo and stepper motors added to Southbend Lathes & Bridgeport Knee Mills. Built a RepRep that made crude parts & put controls on a 14x14x5” tabletop router, Donated both to a museum’s hacker basement in SLC.

Know a 126+ y/o Milwaukee factory that had 130 employees manually milling valves & cylinders, had a night shift as well. They are now about 12 employees and everything is CNC.