The secret lives of snowblowers

Yes, they throw snow. But the mechanical design of residential snowblowers is more interesting than it seems.

In an earlier article on rural life, I talked about our adventures with snow. It’s not that we’re not used to the white stuff: we grew up in Poland, which gets a decent amount every year, and then lived in New England for a couple of years. But until now, save for the occasional shovel duty, large-scale snow removal was always someone else’s job.

Fast forward to today: we own a truck-mounted plow, a pair of snowblowers, and we keep our eyes peeled for weather forecasts November to March. Most of this work is fairly mundane — but unexpectedly, snowblowers are worth geeking out about. For years, I had them pegged alongside lawnmowers, wood chippers, chainsaws, and other crude power tools; as it turns out, they hide a surprise or two.

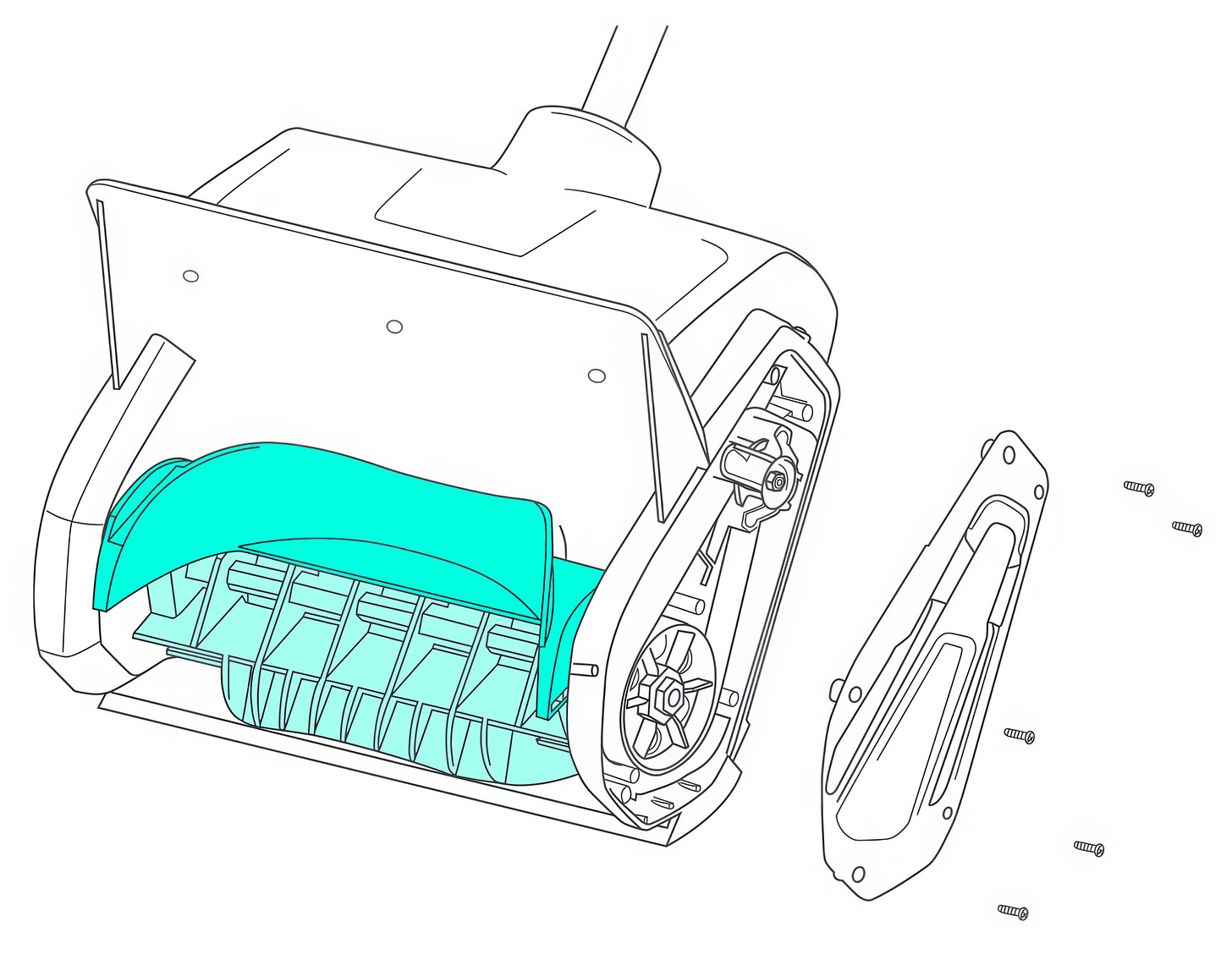

To appreciate the design, let’s start with the proto-snowblower: an electric snow shovel. These lightweight, pole-mounted devices typically employ an injection-molded, dual-edged blade that spins at around 2,000 RPM. With every rotation, the blade shaves off a tiny bit of snow in front of the unit, pulls it underneath, drags it against the back of the unit, then ejects it upward on the upstroke:

The center section of the blade is kept straight to toss the snow 10-15 feet into the air. The outer edges are usually curved inward; this not only engages the material more gradually and reduces vibration, but also helps compress fluffy snow so that it retains momentum once expelled.

The obvious problem with the electric snow shovel is that it throws snow in front of the operator. This might work if you’re making passes perpendicular to a narrow driveway; it’s far less convenient when navigating around obstacles or trying to “shovel” a multi-car parking space.

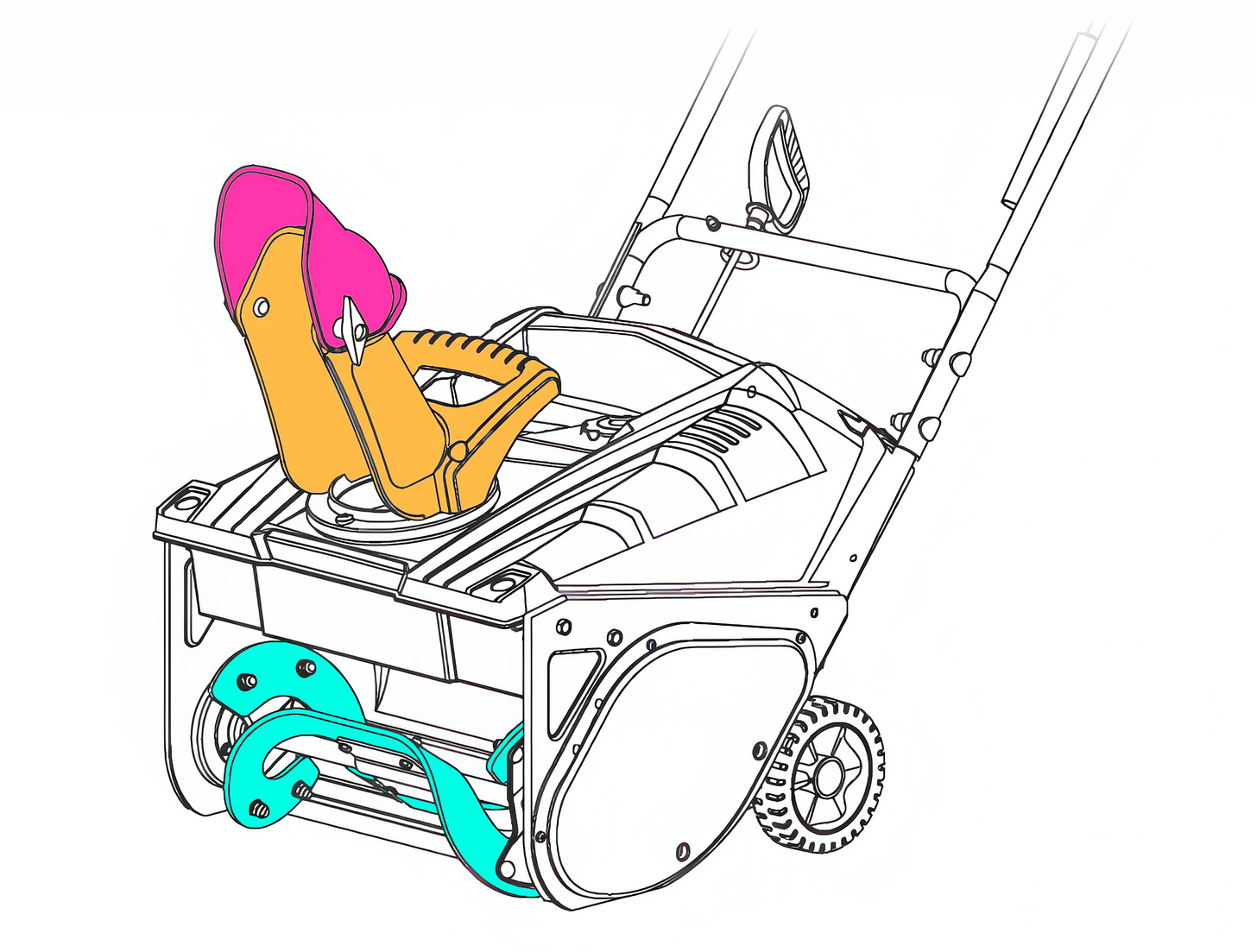

The solution is the single-stage snowblower. The design adds an adjustable chute (orange) to control the direction of the ejected snow, along with a deflector (pink) to set the angle of departure:

The other modification is that the flat section of the blade is narrower, matching the width of the discharge chute. Conversely, the outer edges form more pronounced spirals — essentially a pair of screw conveyors. This is to make sure that no material can collect in the periphery and possibly clog the intake.

Still, the single-stage design suffers from a fundamental flaw: the blade must spin fast in order to throw the snow far enough, and that comes at the expense of torque. For a conventional walk-behind snowblower operating at 1,500 RPM, the torque provided by a small gas engine or a brushless motor might be under 20 ft-lbs. Fresh snow is not a problem, but slush or ice could spell trouble. Increasing power is not necessarily the answer: given enough torque, the flat section of the auger may start climbing up a pile of packed snow instead of tearing it apart!

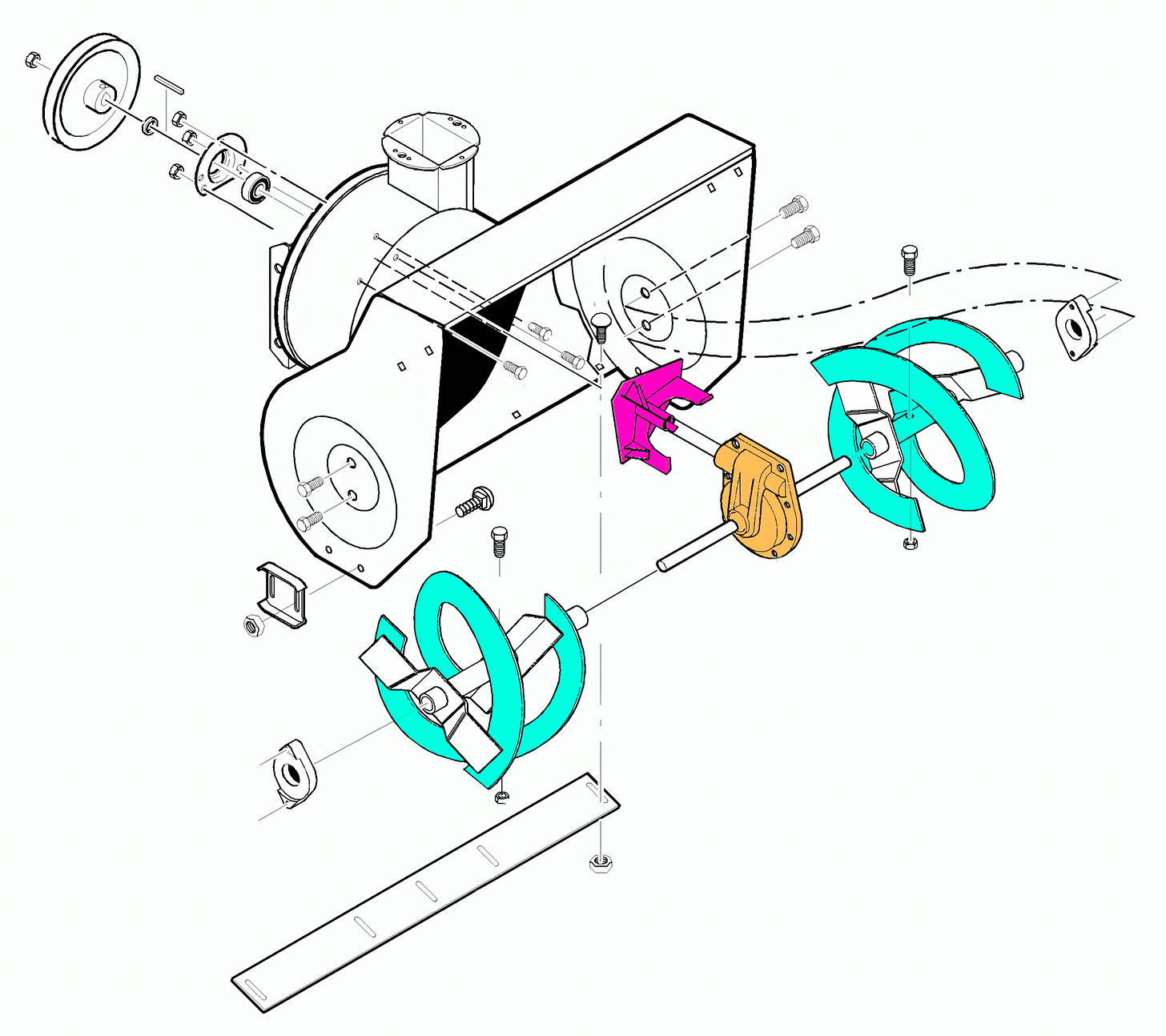

This brings us to the two-stage snowblower. In this design, auger blades (teal) are connected to a drive shaft via a worm gearbox (yellow) that reduces the speed and increases the torque roughly ten-fold:

Just as importantly, the augers are no longer tasked with propelling the snow up the chute; only the spiral bits are retained, often with added serrations to break up ice. Chopped-up material is then transported toward the center of the unit, with minimal lifting action as compared to single-stage designs.

In the back, this loose material is then picked up by a fast-spinning impeller (purple) installed on the drive shaft ahead of the reduction gears. This fan-like structure is commonly equipped with three or four reinforced vanes that send snow up the discharge chute:

The high torque delivered to the auger poses some challenges; there is a risk of bending or breaking the drivetrain if one hits a big rock, a planter, or a similar object hidden under the snow. The most common workaround are sacrificial shear pins made from a brittle alloy (with spares hopefully kept at hand). Some manufacturers opt to reinforce all the at-risk components instead; electric units might be also programmed to sense overload conditions and disengage.

But wait, there’s more! Most snowblowers are quite heavy, typically ranging from 50 to 270 lbs. This mass is beneficial for keeping the device planted on the ground, but it makes it a chore to push it up an incline. For this reason, almost all full-size units are self-propelled, with the engine delivering power to a pair of wheels or a set of rubber tracks.

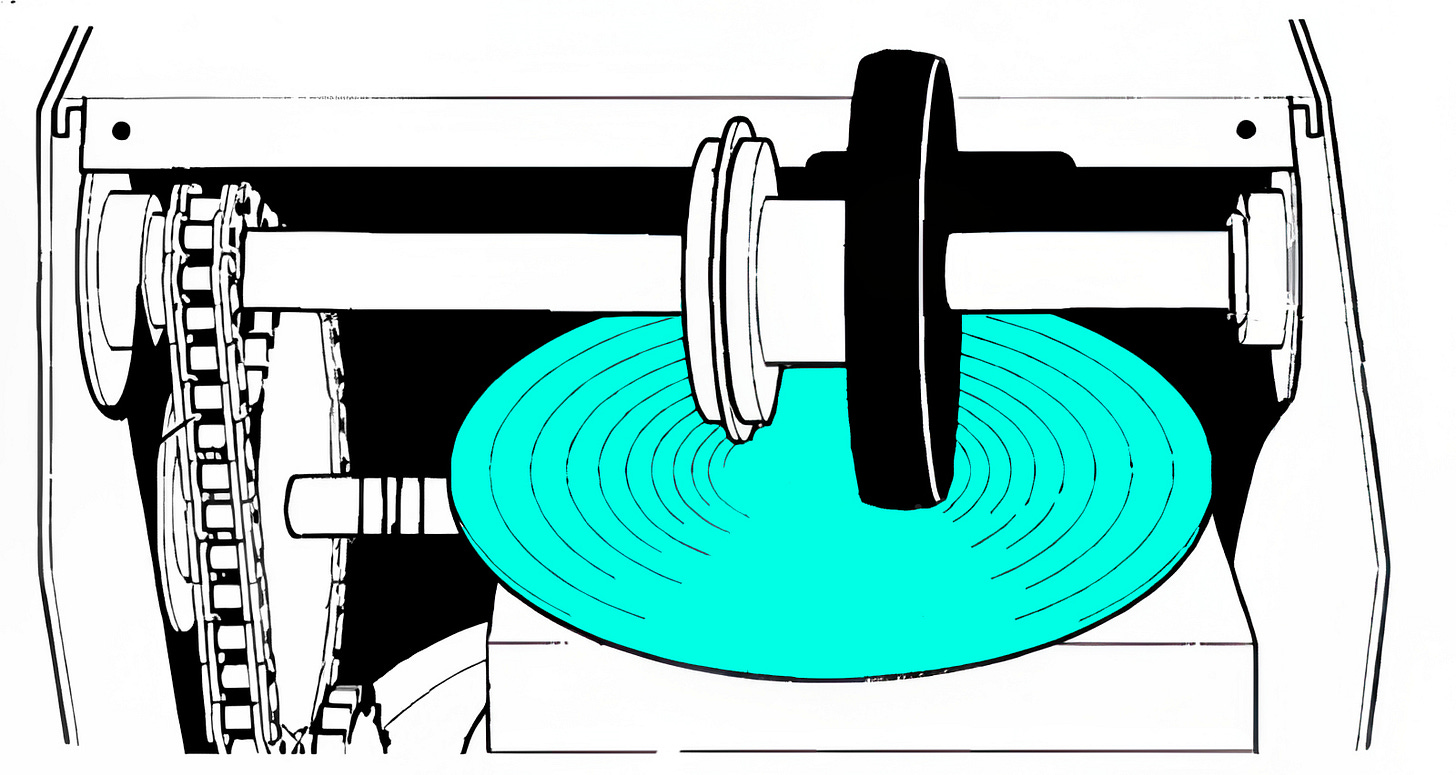

This poses another engineering conundrum. The engines and motors used in snowblowers are designed to run at a more or less constant speed, but the unit’s forward motion must be matched to working conditions and to the operator’s walking pace. Traditional, car-style transmissions are bulky and expensive; instead, the usual approach is a friction disk mechanism, where a rubber-coated wheel (black) is rolling on top of a spinning metal disk (cyan):

If the rubber wheel is moved toward the outer perimeter of the drive disk, the output axle starts spinning faster; if it’s moved toward the center, the rotation slows down. As a bonus, if the rubber wheel is moved past the center of the disk, we get reverse gears.

The approach is simple and cheap, although the rubber wears over time. For this reason, some higher-end snowblowers feature hydrostatic transmission, where a pump with an adjustable swash plate produces a variable flow rate of hydraulic fluid. The fluid is then piped to a simple hydraulic motor to achieve a range of RPM. This transmission is theoretically maintenance-free — although if it does develop problems, they are harder and costlier to repair.

All in all, snowblowers pack a surprising amount of engineering, at least for a residential power tool that usually sells for a couple hundred bucks. Too bad that all this ingenuity is often obscured by shoddy marketing and by brand-loyalty turf wars waged on the internet.

I understand that for a gravel driveway you need a 2-stage. Is this because a 1-stage won't work well if the auger is a few inches above the surface?

Still have a ‘93 Toro 2-stage, 3 forward & reverse. Main shaft bearing seized & was replaced ~10 years ago at considerable expense. It’s been parked for several years, not much snow. Old and neighbors 1 & 2 generations younger help out with my short driveway.